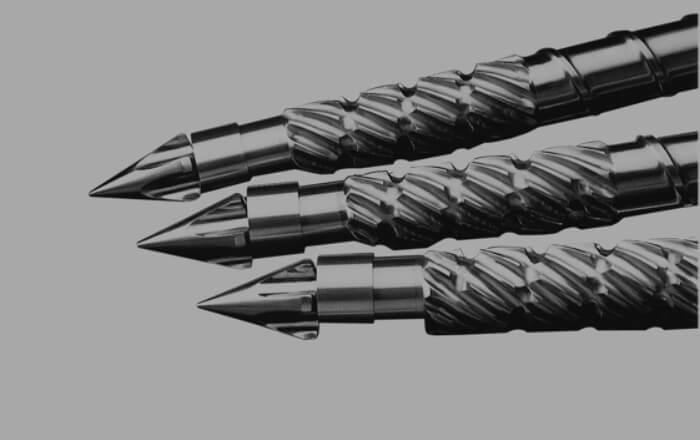

As an important part of injection moulding machine, injection moulding screw directly effects the output product quality. The screw specification should be considered with high priority when selecting the right screw.

About Screw Design

There are three zones in basic design of any screw along its length:

- Feed zone

- Transition zone

- Metering zone

The feed zone means the solid plastic pellets that fed from the material tank to the transition zone where they are compressed. This compression forces the pellets to melt through the action of pushing up and heating device. This is called shearing. The metering zone then conveys the melt material to the front of the screw ready for injection moulding.

In the transition zone the material is compressed by ratio of the feed zone length to the metering zone length, which is called the compression ratio. The length of the transition zone is typically 4 to 7 x the screw diameter in a typical purpose screw.

Another parameter of screw design is the length to diameter ratio (L/D) meaning how long it is compared to its diameter.

When it comes to general purpose screws, longer screws are usually considered because they will produce better melt and produce better products

About Screw Diameter

The screw diameter works in two ways. Firstly it determines the maximum available injection pressure, the smaller the diameter the higher the available pressure, especially for parts that have a long flow length and for materials that are hard to inject.

Secondly the diameter determines the maximum injection available volume. The smaller the diameter, the smaller the injection volume.

It is concluded that, selecting a suitable injection moulding screw for your machine will benefit yourself in energy cost and product quality.